The incredible simple design defines the characteristic and the originality of the SKYRANGER, reaching exceptional performances for a TWO-SEATER UL airplane.

This igenious and unique design simplifies the assembly, use and maintenance to a level you cannot find nowadays anywhere else. The technology used to build SKYRANGER is used as a reference by other aircraft producers.

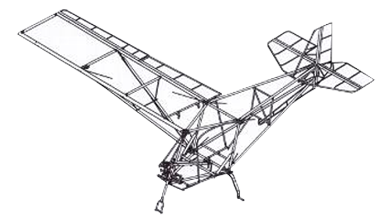

The fuselage construction is patented and features:

No welded tubes, only straight aluminium tubes are used

Only bolts are used for assembly, easy to check by anybody

No composites used for structural components

Other parts are made from stainless steel and plated mild steel.

*Skyranger Romania sells and executes repair services for all engines (Rotax, Sauer, Hirth, Limbach, Continental, etc.)

We also provide repair services to any ultra-light airplane type, canvas change services, electrical system services,

onboard equipment and gauges installation, radio stations and transponders calibration and installation.

1 The mainframe is assembled, fixing together the aluminium tubes and securing them with bolts.

Also in this phase the undercarriage is attached to the chassis so that the resistance can be measured.

2 Next step is to attach all the important parts like cables, fuel tank and commands to the back.

The canvas is then equally spread across the whole airplane fuselage, ensuring that its stretched perfectly.

3 All electrical cables are being connected together and verified in order to be able to attach the engine.

The engine is mounted and the propellers are connected, in order to be able to test the engine and RPM.

4 Finally, the wings are attached to the fuselage and the engine lid is fixed in position with bolts.

From now on the airplane runs trough a set of tests and fine tuning before being ready to ship to a new client.

We manufacture and install various parts from composite materials (Fiberglass, Carbon Kevlar)